Want to keep a Restoration Log? Post it here! You can include photos. Suggested format: One Restoration per Thread; then keep adding your updates to the same thread...

-

zeerx

- honda305.com Member

- Posts: 56

- Joined: Tue Nov 26, 2013 8:48 pm

- Location: Haverhill, MA

Post

by zeerx » Wed Sep 17, 2014 12:45 pm

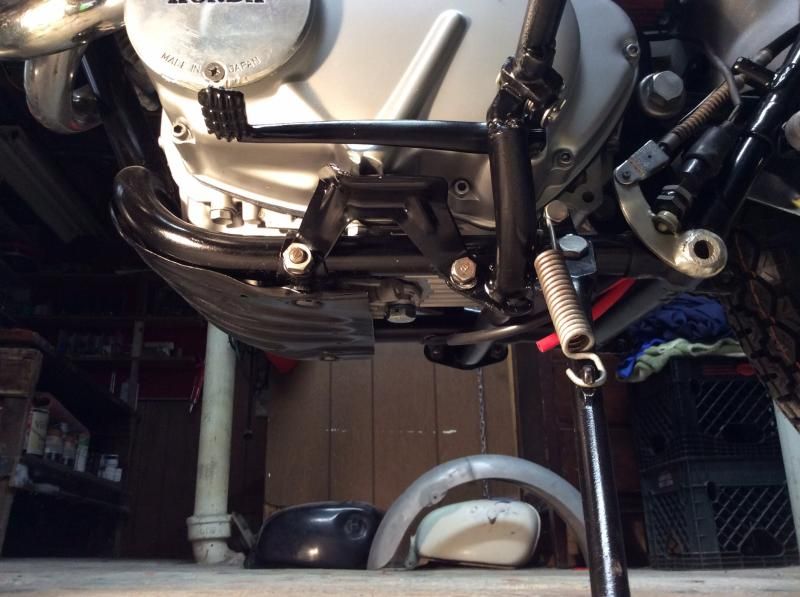

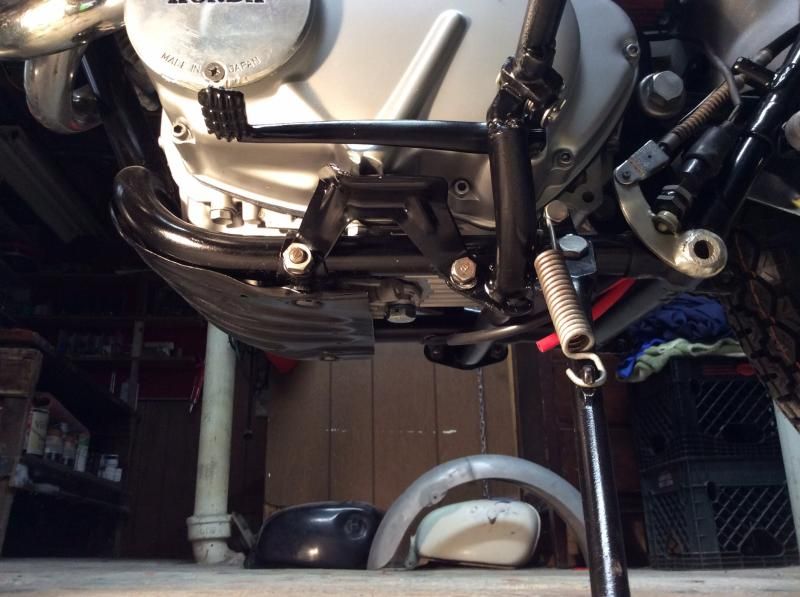

Update. Finally got the bike on its wheels without support.

I've owned a few of these bikes in the 60s and 70s but I got this bike with something on it I never knew existed. Under the left foot peg there's a small case guard that bolts up with the pegs. The PO of all the other bikes I owned must have not bothered to reinstall it when the pegs were removed.

Dropped in the half dead battery to try out the electrics. Tail light and head light didn't come on. Took me 2 hours to chase the gremlins away. The head light ended up being a broken wire in the handlebar switch. The tail light was a corroded terminal.

Tank is still a work in progress.

'99 ZRX1100

'05 DRZ400S

'66 CL77

'78 KZ1000LTD

'12 F-150 (Ford)

-

zeerx

- honda305.com Member

- Posts: 56

- Joined: Tue Nov 26, 2013 8:48 pm

- Location: Haverhill, MA

Post

by zeerx » Sun Oct 05, 2014 4:46 pm

Before and after media blast.

'99 ZRX1100

'05 DRZ400S

'66 CL77

'78 KZ1000LTD

'12 F-150 (Ford)

-

deafanddiabetic

- honda305.com Member

- Posts: 258

- Joined: Thu Jun 19, 2014 6:04 pm

- Location: Nebraska

Post

by deafanddiabetic » Sun Oct 05, 2014 11:12 pm

Really loving this, excited to see it all put together.

-

smccrory

- honda305.com Member

- Posts: 40

- Joined: Fri Aug 08, 2014 4:49 pm

- Location: Columbus, Ohio, USA

Post

by smccrory » Sat Jan 03, 2015 11:04 pm

Scramblers are so damned sexy, and yours is coming back to life nicely - keep the progress reports coming!

-

zeerx

- honda305.com Member

- Posts: 56

- Joined: Tue Nov 26, 2013 8:48 pm

- Location: Haverhill, MA

Post

by zeerx » Sun Jan 04, 2015 6:52 pm

The bike is all together except for the tank. No need to hurry because I won't be able to start it until spring. I want to get it through a coupe of heat cycles and head retorques to keep the top end nice and tight. If I can figure out how to post a video I'll record the initial startup. When I get a tank done I'll post a pic. Stay tuned.

'99 ZRX1100

'05 DRZ400S

'66 CL77

'78 KZ1000LTD

'12 F-150 (Ford)

-

zeerx

- honda305.com Member

- Posts: 56

- Joined: Tue Nov 26, 2013 8:48 pm

- Location: Haverhill, MA

Post

by zeerx » Sun Jan 04, 2015 6:53 pm

The bike is all together except for the tank. No need to hurry because I won't be able to start it until spring. I want to get it through a coupe of heat cycles and head retorques to keep the top end nice and tight. If I can figure out how to post a video I'll record the initial startup. When I get a tank done I'll post a pic. Stay tuned.

'99 ZRX1100

'05 DRZ400S

'66 CL77

'78 KZ1000LTD

'12 F-150 (Ford)

-

zeerx

- honda305.com Member

- Posts: 56

- Joined: Tue Nov 26, 2013 8:48 pm

- Location: Haverhill, MA

Post

by zeerx » Thu Jan 22, 2015 1:14 pm

OK. Out of the 4 tanks I have I was able to get two straightened out. The first has the knee pad brackets but the badge pockets were filled in with bondo that I had to dig out. I was hoping the badge tabs were still there....they were. The inside was pretty rusty so I used Evaporust the clean it out. Then I used the POR15 process to seal it. It was the first time I had used it and it turned out pretty good. If you try it follow the directions to the letter. There was a big dent in the top that I had cut out and a patch re-welded. There is a lot of surface corrosion that would mean covering the whole tank with bondo to fix. I'm gonna skip it because it's just not worth the trouble. Any defects that come through the final finish will give the tank 'character'.

The second tank is in better shape rust wise and again the PO filled in the badge pockets and also removed the pad brackets (why do people do things like that). If I use it I'll use some double sticky tape on the knee pads to hold them on. I can probably get away with using the tank without sealing the inside. No surface rust.

The first tank has the outlet for the crossover pipe but my petcock does not. I'll just put a rubber nipple on it to block it. The second does not have a crossover pipe.

Now I just need a little warm weather to take the tanks outside to paint. I'll post the finished product soon.

'99 ZRX1100

'05 DRZ400S

'66 CL77

'78 KZ1000LTD

'12 F-150 (Ford)