For the home plating specialistGee, Adam, you could build your own Frankenstein with that puppy! Probably make his bride, too.

So, you gonna wear a white lab coat while you are plating, have a hump on your back and talk with an Eastern European accent? I nid more zeenk to plet my motaur-sy-cool. Sorry, it was a tough day, today. regards, Rob Ya that’s what I’m beginning to realize. My setup may be a little to much but maybe not. We need to establish the boundries in order to advise the future platers.

Let’s all try to find the best setup possible if you were starting from scratch. That way, new platers know what to look for or buy right off the bat for the optimum system. You can always go easier and cheaper once we know the best solution. What is the Minimum current and Maximum current for 90% of the plating scenarios? Then, we can select the best power source for these criteria. Then we can select a proper rheostat to accomplish the goals of the setup. Adam,

Sorry to have left you hanging this morning...I had to judge a science fair today so I didn't have much time, but I did want to steer you away from ordering a 1 kilowatt rheostat. You asked how much plating current would be needed for small and large parts. I don't know what small or large is to you, so I have no answer. All I can do is repeat what I've previously noted: it depends on a bunch of things, including the surface areas of the part and the zinc anode, and a host of other variables unique to your set-up. I guess 'unique' is the operative word here, as everyone finds stuff in their junk-box that 'should work'. That's what I do, and that's the fun of it for me. 90% of the people don't follow others' recipes, methods or construction (all of which have been described in this thread). I think that's a good thing--it expands the 'gene pool'. I believe that if you or anyone else used a setup identical to mine they would achieve the same results as I have, and which are satisfactory to me. In other words, I don't have magic. But if you want to plate faster or plate larger parts, or use a higher voltage power supply, then all I can offer are suggestions based on what I believe to be the operative factors in the process. The rest of it is up to your junk-box and your willingness to tinker. And there are many who choose not to tinker with it. For those, there are turnkey plating kits available on-line. In re-reading this post I see a rather heavy tone--I apologize for that (easier to say sorry than to re-write) and trust you will not feel that I'm quitting on your question. Lastly, I'm pretty confident that 99% of home platers will not need to buy the 1 kilowatt rheostat! Cheers, Wilf I don't need to be in the 1% of platers. I guess I'm just placed there because of the power supply that I ended up with and thinking that more current is needed to put more parts in the bath or to get faster results. I'm not opposed to changing the power supply or anything in the setup. That’s what I'm asking everyone. I want to start plating again.

I have only plated two small parts so I have no working knowledge of the vast majority of plating situations. It sounds to me like .300 amp is the normal optimum current. Possibly going up to a higher amount of current for bigger parts or more parts. If I have a rheostat and can control the amount of current to my parts than I can always control it down to .300 amp regardless of the amount or size of parts in the bath. Is this right? The largest part that I could put into the bath would be 10-12 inches long, maybe something like a large brake stay. Maybe count two of these side by side as the largest part/parts that I would be plating. Maybe looking at pushing 1amp through the system is way overkill. Like I said, I have only plated two things. What is the highest amperage that most people see needing to plate 99% of things. If I can find out this mystery variable (max current most people use) then I can come back down and join the 99% by adjusting the current that I plan to put through the system. This one variable dictates everything in the setup. My set up is just a 1 gal plastic pail and the entire depth and ID are enshrined in zinc plate. Pretty sure I posted a picture here. The reason for the circular anode is plating is line of sight for the most part and I wanted even plating without multiple trips thru the bath.

I use a 1amp 12 vdc power supply for the reasons mentioned by Wilf. After burning out a smaller one by pushing the amps, I found this one (never thrown anything useful out) in my electrical junk cabinet and then bought the rheostat when my puny radio scrounged rheo fried. I thought I did right with the rheo I bought base on wattage rating (know better now thanks to Wilf, a molder of future Big Bang Theory cast members) and have pushed it to just under 1 amp many times since getting it last winter. I did all the parts on my CL77 with the previously fried parts set up and later this set up. So maybe I'm just lucky that my big old Ohmite rheo has not bitten the dust. I will say that with this new bath, I'm running much lower voltages and currents and getting great results. I'm doing all the parts for a '66 T120R Triumph currently. Yeah, I know. Should be cad. Zinc is fine and safer. My rheo is a Model K. About 3 inches in diameter. But is is about 1000 ohms so adjustment is not as fine as a smaller ohmic rating would provide. But then again, just how fine of an adjustment do you need? I'm happy. Surface area of the parts is the big variable as Wilf mentioned and that's what requires you to adjust the rheo. If I do small parts, I put as many as I can string along my copper hanging wire. If I do big parts, I only do 1 or 2 at a time. Really long parts get done half at a time. If my rheo eventually fries, I'll probably just get a similar one or maybe think a bit more about the right way to do this, follow Wilf's guidance and try a different rating. But to be honest, for what this rheo cost me, versus what it would have cost to get all the parts I've plated done commercially, a new rheo is a small price to pay. regards, Rob

Hello folks. I thankfully stumbled across this forum when looking for options to clean up some bolts and hardware for a 69 PC50 Honda moped that I am restoring. Last night, I read all 29 pages of this thread and jotted down the "trial and error" points that different members had found worked for them. My plating needs are pretty minimal for this project. About 15 -20 misc. small pieces like bolts, washers, brackets, etc. Likely the largest pieces would be the cranks for the pedals of the moped.

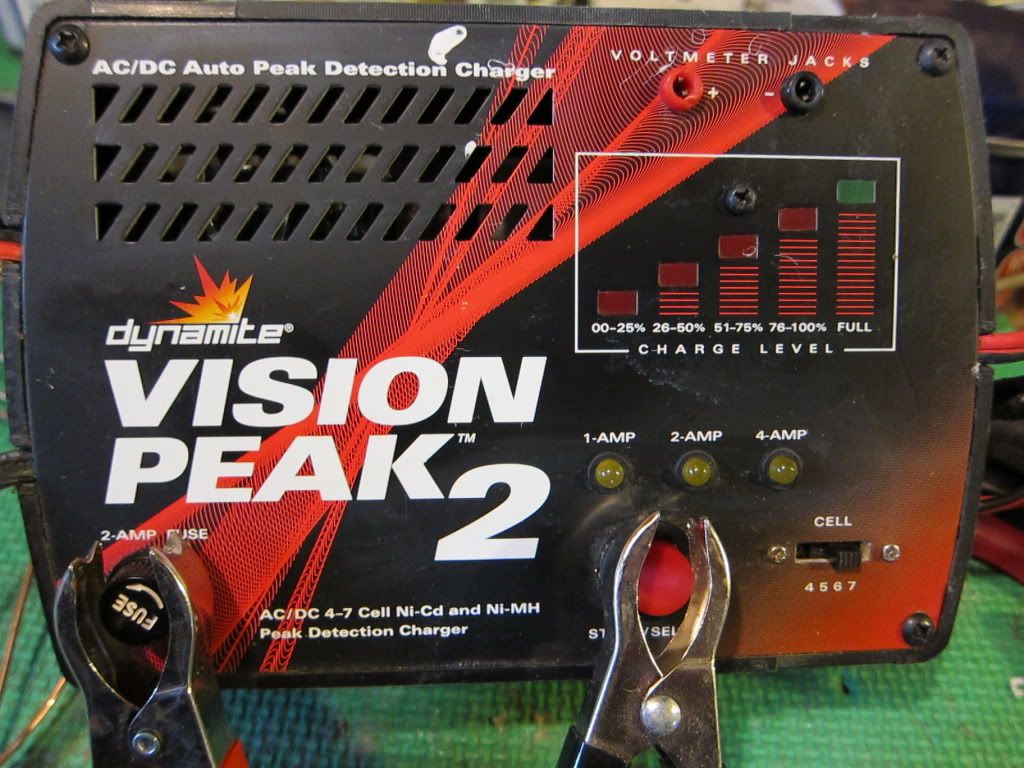

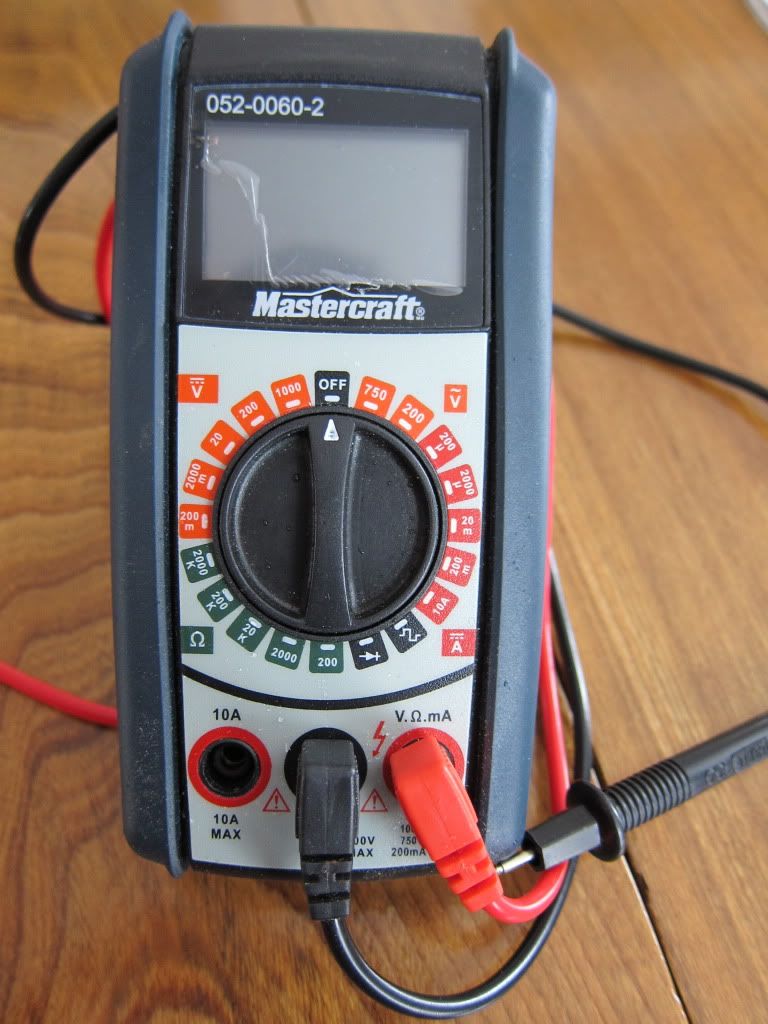

I'd like some opinion of what I've built so far. I think that based on what I've read from the learning experiences of others, the only piece I need is my rheostat. Also, I don't have my built with the roofing material zinc strips as since my inlaws are fishermen, I have lots of slightly used zinc pieces off theif fishing boats.  And here is my charger. Its capable of 1, 2 or 4 amp and from what Snakeoil mentioned on page 18 of this thread (i think thats where??), 1 amp seems about the best. This charger was used for NIMH batteries in my remote control truck.  I have a mulimeter as well but not sure what setting it needs to be at for this project?? Will the multimeter jacks on my charger be of any use?? I've never used them before and am pretty dumb when it comes to my multimeter as well.  So if I can track down a 50watt (500 ohm) rheostat, I should be set. Anyone care to offer an opinion on my set up? pc50fixer,

Your bucket and zincs look fine. Hard to say how the charger will respond as a power source because they often sensing circuitry built into them that does lend itself to our plating needs. You can give it a try-- Set it to the 4 cell position and check the voltage with your meter set to dc volts, 20 volt range. Then mix up your electrolyte, hook it up and see what happens. It looks as though the output is fused so you shouldn't be at risk of smoking the charger. Wilf

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||