1966 CB77 Restoration Project

Sounds plausible, Chase. That might better explain the higher gouge on the fork. Anyway, it’s all sorted now. On to other things.

cknight wrote:It's probable that one of the front brake stay bolts failed or loosened, allowing the brake plate assembly to rotate when the brake was applied. This can cause the brake cable to wind-up around the hub, locking the front brake, and scarring some parts along the way. Regards, Chase

As an update, I can report that, with major help from Loud Mouse (thank you!), the engine is almost ready for reassembly. On Tuesday, between storms, I took the stripped and degreased crankcase halves to a vapor blaster in a neighboring state. Photos below. I'd have to say that the results were...mediocre. The fellow doing the work was a nice guy, but media blasting is not his first priority. He does it as a side business and seemed somewhat distracted. Other parts he'd completed that I saw at his shop looked much better than mine when done. Still, they'll do.

I've picked up a NOS DID rim for the rear wheel. I'll be either re-zincing the spokes or buying a new set. There'll be a new adventure in wheel building coming soon. The front rim looks okay. I couldn't find a NOS DID rim for it, but It polishes up fairly nicely. I'll probably replace the spokes and buff out both hubs to a satin shine.

I've finally collected all the missing parts for painting, except the right side air filter cover. Since I'll be painting all of the gray parts myself, I'm not in a rush to get one. I'll be stripping the parts to be painted red and take them to a professional painter when I can find one willing to do the work. That's another thing I'd like to learn to do.

The gas tank has been filled with EvapoRust for about a week and is looking pretty good. I'll let it sit for a bit longer, then drain it, rinse it out and coat the inside with thin oil. I've found a used petcock for it and after cleaning, gave it a new rebuild kit and it's ready to go.

Yesterday, I stripped the oil pump down and gave it a good cleaning. It was completely stuck in goo. New gasket and new cover screws. The gears looked ok. I tried to see how well it pumped by immersing the bottom part in oil and turning the drive gear with a clean 6" diameter buffing wheel. It moved oil, but I don't know if it's up to par. I'll have to risk it.

Zinc plating to be started soon. I'll start with all that's needed to get the engine assembled and then branch out from there.

The crankcase halves and other parts at the blaster. For those that recall my damaged top case, I solved the problem by finding a used top case (for $40) with an engine serial number only 190 greater than the frame number:

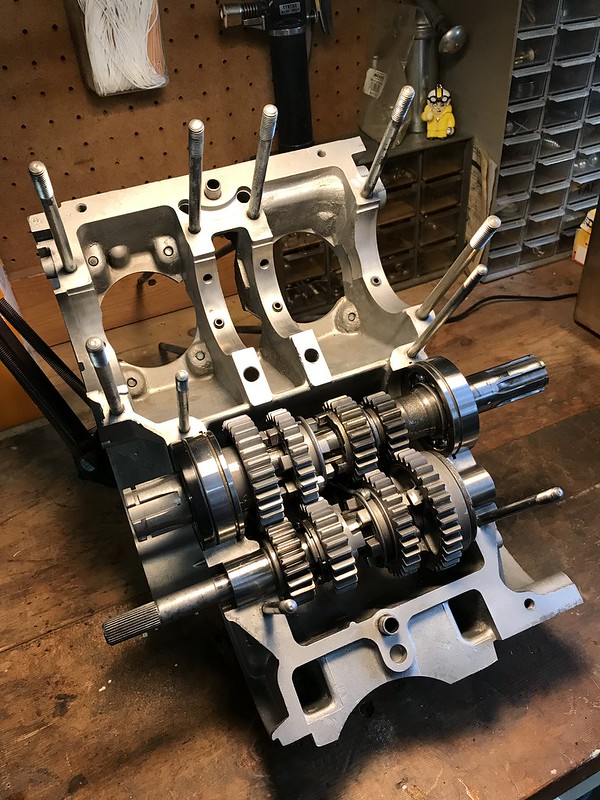

Most of the major engine parts ready for assembly:

I've picked up a NOS DID rim for the rear wheel. I'll be either re-zincing the spokes or buying a new set. There'll be a new adventure in wheel building coming soon. The front rim looks okay. I couldn't find a NOS DID rim for it, but It polishes up fairly nicely. I'll probably replace the spokes and buff out both hubs to a satin shine.

I've finally collected all the missing parts for painting, except the right side air filter cover. Since I'll be painting all of the gray parts myself, I'm not in a rush to get one. I'll be stripping the parts to be painted red and take them to a professional painter when I can find one willing to do the work. That's another thing I'd like to learn to do.

The gas tank has been filled with EvapoRust for about a week and is looking pretty good. I'll let it sit for a bit longer, then drain it, rinse it out and coat the inside with thin oil. I've found a used petcock for it and after cleaning, gave it a new rebuild kit and it's ready to go.

Yesterday, I stripped the oil pump down and gave it a good cleaning. It was completely stuck in goo. New gasket and new cover screws. The gears looked ok. I tried to see how well it pumped by immersing the bottom part in oil and turning the drive gear with a clean 6" diameter buffing wheel. It moved oil, but I don't know if it's up to par. I'll have to risk it.

Zinc plating to be started soon. I'll start with all that's needed to get the engine assembled and then branch out from there.

The crankcase halves and other parts at the blaster. For those that recall my damaged top case, I solved the problem by finding a used top case (for $40) with an engine serial number only 190 greater than the frame number:

Most of the major engine parts ready for assembly:

Last edited by Seadog on Fri Mar 09, 2018 8:08 am, edited 1 time in total.

Great progress, Seadog.

Hoping to get back to my project when the weather improves. I'm doing some work on a friend's Gilera engine at the moment whch is an interesting challenge.

Dod you check the periphery of the oil pump chambers? Scores there are not good news.

Keep up the good work.

G

Hoping to get back to my project when the weather improves. I'm doing some work on a friend's Gilera engine at the moment whch is an interesting challenge.

Dod you check the periphery of the oil pump chambers? Scores there are not good news.

Keep up the good work.

G

Seadog wrote:As an update, I can report that, with major help from Loud Mouse (thank you!), the engine is almost ready for reassembly. On Tuesday, between storms, I took the stripped and degreased crankcase halves to a vapor blaster in a neighboring state. Photos below. I'd have to say that the results were...mediocre. The fellow doing the work was a nice guy, but media blasting is not his first priority. He does it as a side business and seemed somewhat distracted. Other parts he'd completed that I saw at his shop looked much better than mine when done. Still, they'll do.

I've picked up a NOS DID rim for the rear wheel. I'll be either re-zincing the spokes or buying a new set. There'll be a new adventure in wheel building coming soon. The front rim looks okay. I couldn't find a NOS DID rim for it, but It polishes up fairly nicely. I'll probably replace the spokes and buff out both hubs to a satin shine.

I've finally collected all the missing parts for painting, except the right side air filter cover. Since I'll be painting all of the gray parts myself, I'm not in a rush to get one. I'll be stripping the parts to be painted red and take them to a professional painter when I can find one willing to do the work. That's another thing I'd like to learn to do.

The gas tank has been filled with EvapoRust for about a week and is looking pretty good. I'll let it sit for a bit longer, then drain it, rinse it out and coat the inside with thin oil. I've found a used petcock for it and after cleaning, gave it a new rebuild kit and it's ready to go.

Yesterday, I stripped the oil pump down and gave it a good cleaning. It was completely stuck in goo. New gasket and new cover screws. The gears looked ok. I tried to see how well it pumped by immersing the bottom part in oil and turning the drive gear with a clean 6" diameter buffing wheel. It moved oil, but I don't know if it's up to par. I'll have to risk it.

Zinc plating to be started soon. I'll start with all that's needed to get the engine assembled and then branch out from there.

The crankcase halves and other parts at the blaster. For those that recall my damaged top case, I solved the problem by finding a used top case (for $40) with an engine serial number only 190 greater than the frame number:

Most of the major engine parts ready for assembly:

'60 C77 '60 C72 '62 C72 Dream '63 CL72

'61 CB72 '64 CB77 '65 CB160

'66 Matchless 350 '67 CL77

'67 S90 '77 CB400F

'61 CB72 '64 CB77 '65 CB160

'66 Matchless 350 '67 CL77

'67 S90 '77 CB400F

Apologies for the size of the photos I posted yesterday. When I went back to look at my thread on my iPad, I couldn't read the text because it was so small. I've resized them and will be more careful in future.

Thanks, G. I searched the forum on rebuilding oil pumps and saw your photos from some time back. My pump wasn't scored like some of those I saw in earlier posts. There were some light scratches, but nothing deep. I can take photos if you'd like to take a look.

I've been watching your progress on the Gilera on Facebook. Very interesting.

Thanks, G. I searched the forum on rebuilding oil pumps and saw your photos from some time back. My pump wasn't scored like some of those I saw in earlier posts. There were some light scratches, but nothing deep. I can take photos if you'd like to take a look.

I've been watching your progress on the Gilera on Facebook. Very interesting.

G-Man wrote:Great progress, Seadog.

Hoping to get back to my project when the weather improves. I'm doing some work on a friend's Gilera engine at the moment whch is an interesting challenge.

Dod you check the periphery of the oil pump chambers? Scores there are not good news.

Keep up the good work.

G