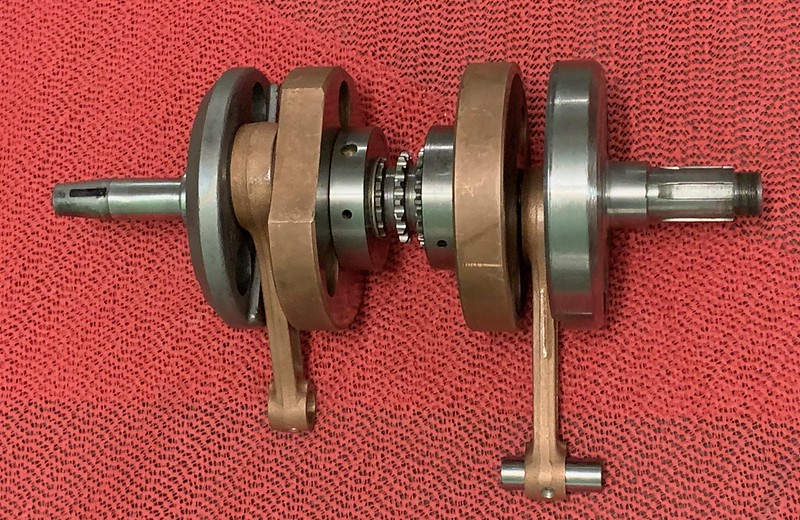

All was well until I needed to find an alternater-side crank web and shaft.

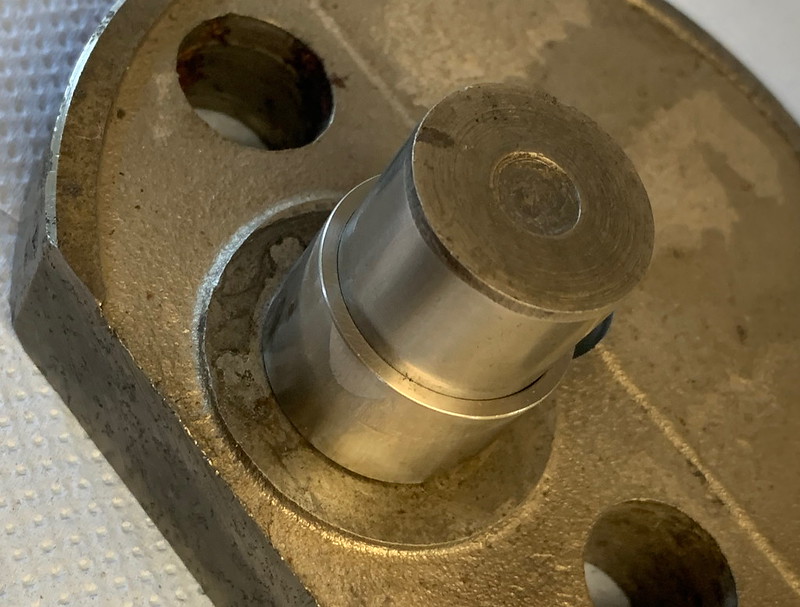

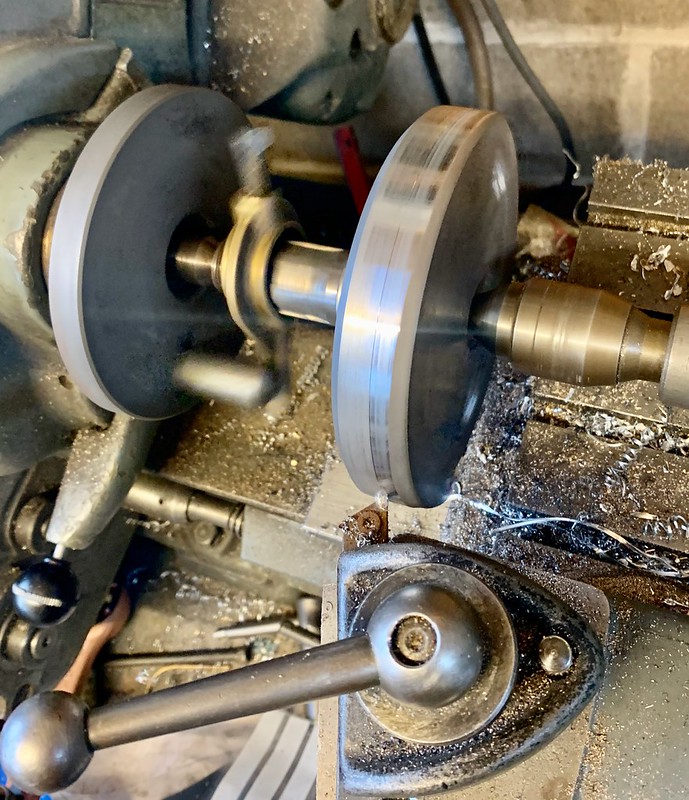

The only one I could find had a badly corroded section where the starter sprocket fits. Initially, I looked on eBay to try and buy a better part but the ones that turned up were worse than the part I had. Eager to get this one finished I decided to try out the little Dumore toolpost grinder I purchased last year.

Originally I hjad planned to make a sleeve to fit over the reduced dimater shaft but precision grinding is a very slow process so I had to settle for just cleaning up the corrosion and seeing where I ended up.

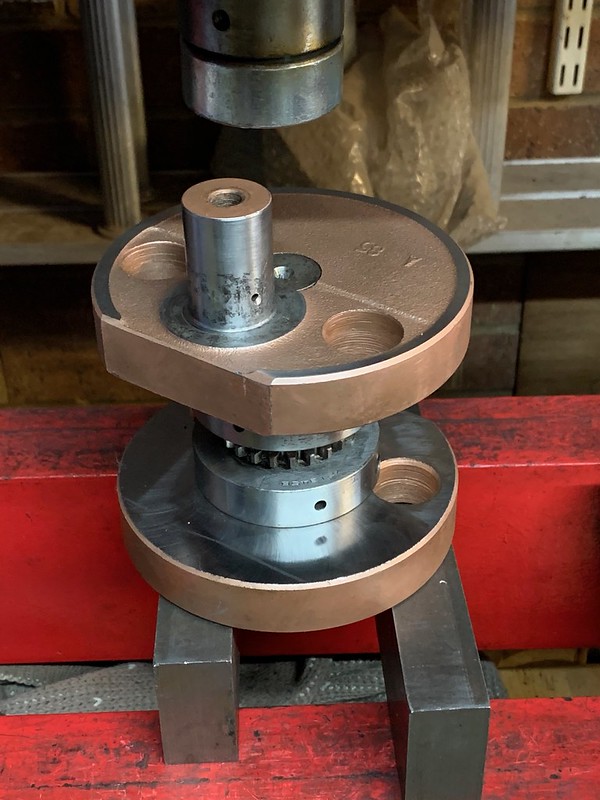

As it happened I was able to get a nice surface at 19mm diameter which is just 1mm down from the original shaft size. Of course the starter sprocket bush was now too slack so I had to press in a new one and bore it to size.

That fixed the bearing but I now needed a suitable oil seal to fit the new shaft. I discovered that I could get a replacement with a 19mm bore so all was well.

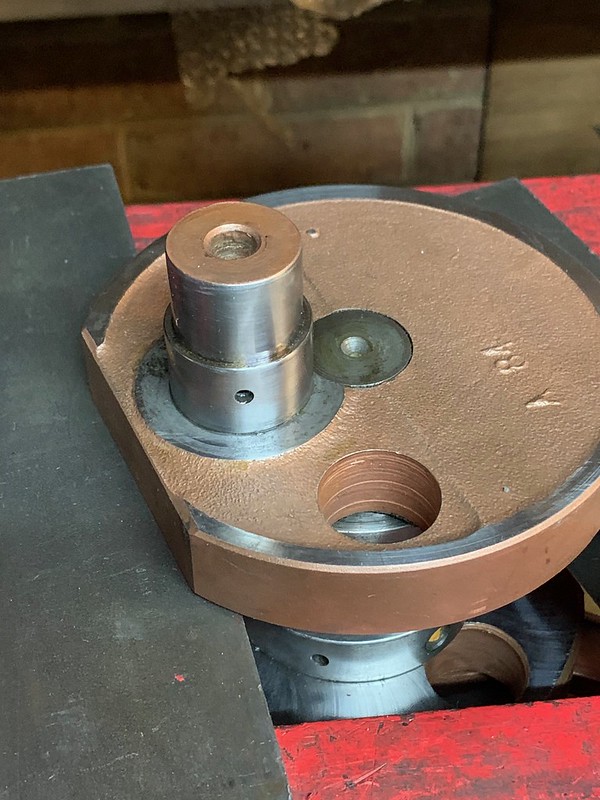

I am pretty pleased with how this turned out. The rotor taper is a little shorter than standard but I'm confident that it will be OK.

The starter clutch appears to work fine on its 'new' shaft, too. The main bearing journal also suffered from corrosion but I can fix that by pressing on a ball-race in place of the original roller bearing.

Another part rescued. :-)

G