Next order of business was carb rebuilds. The original square-bowl carbs that were on the bike when I bought it had seen better days. Back when I first got it running, I had spent quite a while cleaning out aluminum oxide stalagmites and stalactites from the left carb bowl. Apparently a fair amount of moisture had gotten in and done its thing over time.

This is was my first attempt at cleaning (from years earlier):

The "new" engine (which is from '64, one year earlier than the frame) came with the round-bowl carbs installed when I bought it. I don't think these are correct for a '64, and I know they aren't correct for a '65, but I'm not building a showroom-stock 100% correct motorcycle. The round-bowl carbs were in much better shape but nonetheless did need some attention. I cleaned them carefully with various brass wire brushes to remove the surface oxidation. I wasn't going for a polished or shiny finish, just something that looked serviceable and relatively new again. Here are the results of my efforts: untouched carb on left, cleaned on right.

I bought the Keyster kits and ended up using the gaskets, o-rings and air screws with new screw springs. I kept the original jet holders but haven't decided on mains yet. I know Kei-Hin (OE) jets are allegedly far superior to the Keysters, just need to decide on a size once the bike is running. I used new Honda needle valves and brand new Honda brass floats. The bowl bail clips and choke mechanism parts will all go out for new zinc plating.

The bowls did have a bit of pitting and oxidation, and after cleaning them up I was left with some pinholes that were a bit troubling. Knowing that JB-weld is insoluble in gasoline, and that no one would ever see it, I mixed up a small batch and filled in the voids.

It's more or less visible in the following images:

My last major hurdle was getting the flanges flat. I know that over-tightening the flange nuts will warp the flanges, which can lead to "sticky" slides. I decided to correct any warping that had previously occurred, and flatten the flanges to better-than-stock specs. So I bought a small square of glass and decided to lap them.

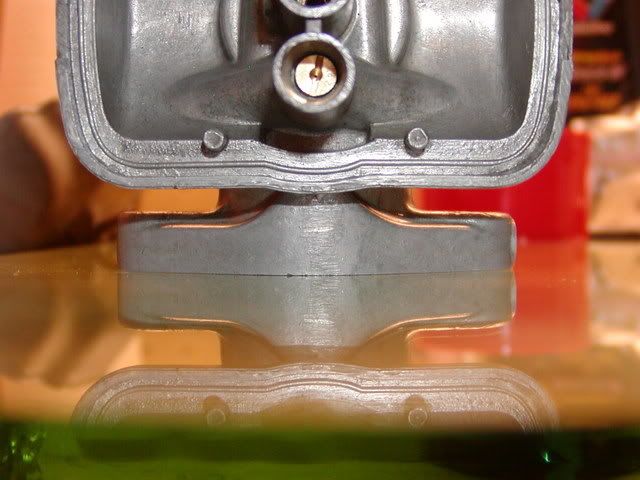

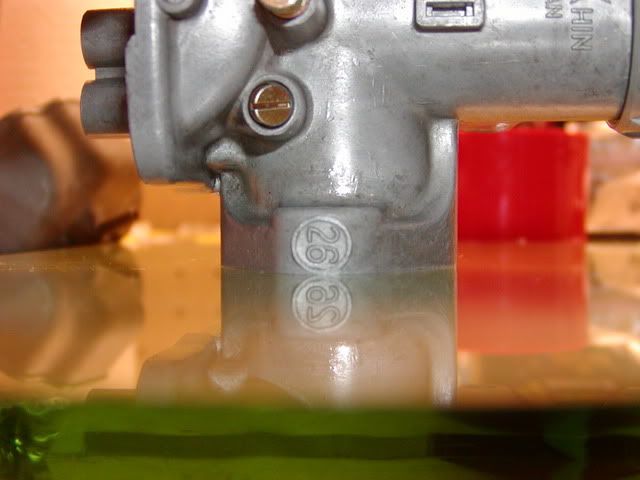

Before pictures from one carb:

I checked them for warping in two planes, as shown by the two different angles of the pictures. I could get a feeler gauge between the carb and the glass, somewhere around 0.010" if I recall correctly. Lapping to correct this was a long, laborious process. I used 600 and then 800 grit sandpaper, with WD-40 as a lubricant. The glass was clamped to the bench and I used a combination of linear back-and-forth movements with circular sanding to keep things even.

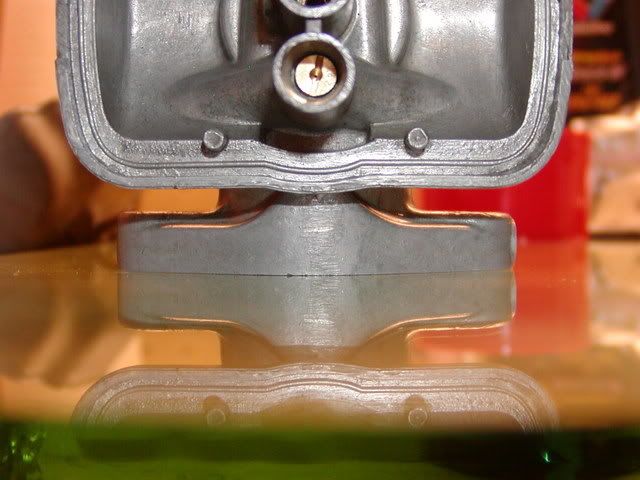

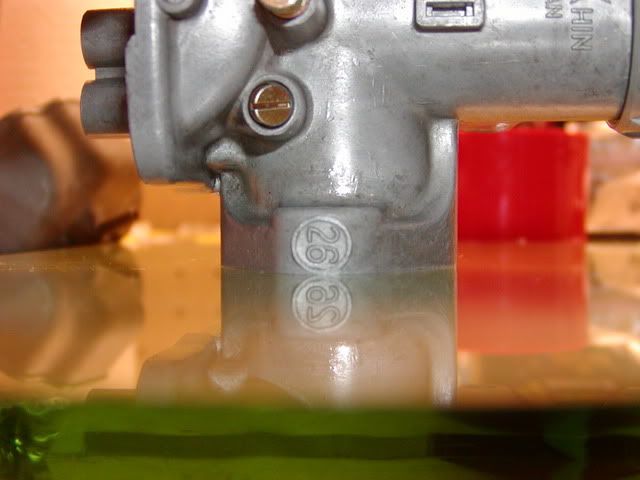

Results:

Huge improvements as you can see. Now I know I'll never over-tighten the flange nuts...;-)

So the flanges should remain flat and true for as long as I own the bike.

I also lapped the phenolic spacers, which together with the lapped carbs should prevent any intake air leaks.

Overkill? You tell me. I had fun with it.